- Description

- Advantages

- Success stories

Description

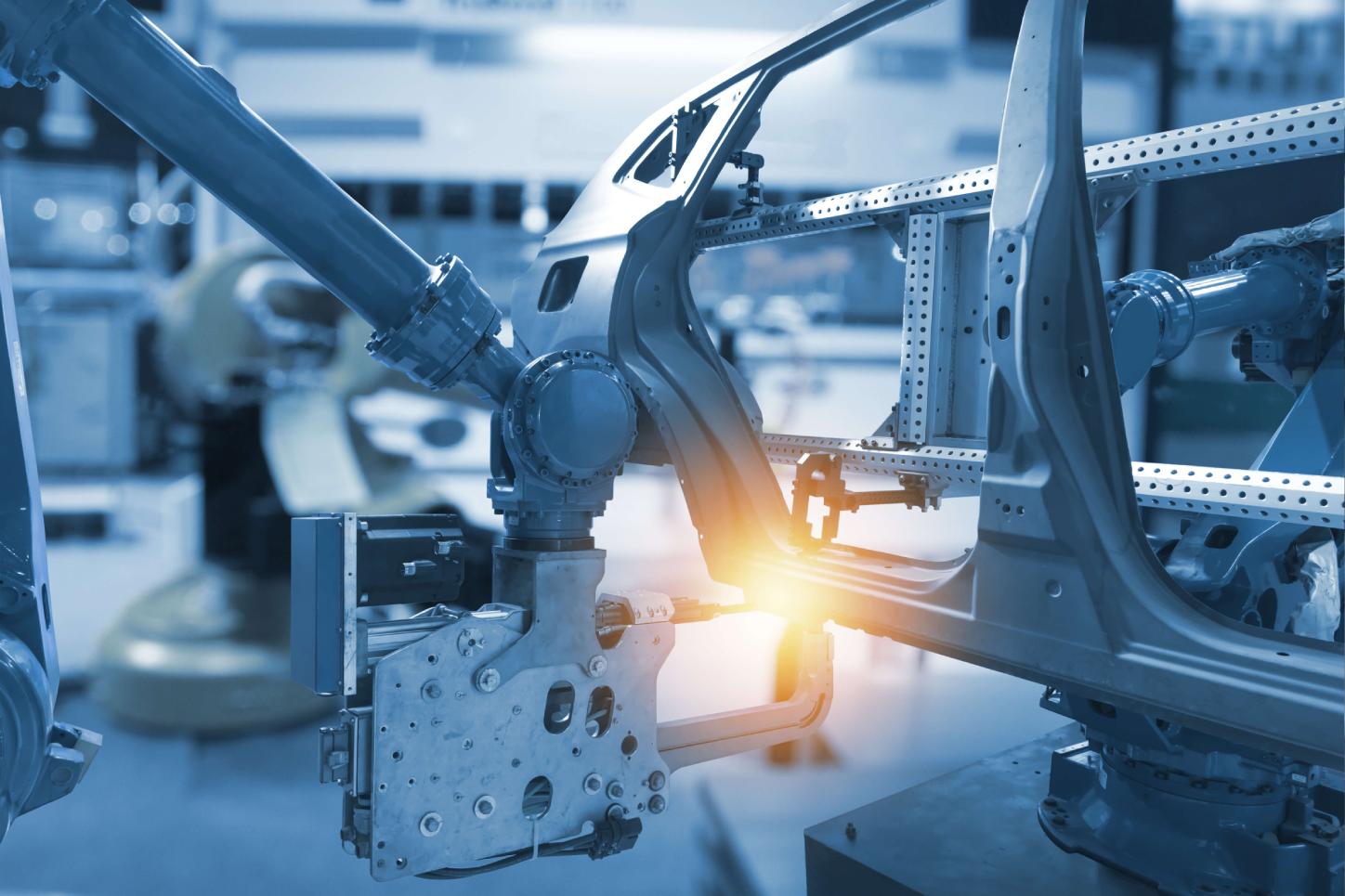

Loire Gestamp has a long history in line automation, delivering turnkey projects with the ideal and optimized automation for each production process.

Different equipment is possible for the different zones of a production line:

- Loading zone or front of line (FOL): format loading trolleys, robots with automatic gripper change or feeders for format destacking, etc.

- Interpress zone: robots, feeders, etc.

- End-of-line (EOL) zone: parts autoracking, robots, feeders, etc.

As a result, efficiency is maximized and the performance of existing equipment is increased. In addition, for better quality and process control, thermographic cameras, vision cameras and detectors can be installed.

Loire Gestamp is able to perform feasibility studies for automating production lines, including detailed simulations, and then propose the most versatile solutions to the customer.

Advantages

Cycle time reduction

Reducing the cycle time to complete an operation optimizes the production process and increases the overall productivity of the production line. This achieves greater production capacity and a faster response to market demand.

Reduction of production costs

Errors and waste are minimized, resulting in savings in materials and resources. Enables more profitable production by optimizing processes and reducing expenses associated with product manufacturing.

Success stories

Line automation

+ than 100 supplied

Germany, Spain, Portugal, France, United States, Mexico, Brazil, China, India, United Kingdom, Turkey...

Loading and unloading robots, transfer feeders, autoracking of parts, etc.

Loire Service

Proactive support, leading real and immediate solutions.

We are the strategic partner for the complete line, both in annual packages and with personalized service packages. We know the variables that adapt to our clients' business and we continually guide them in improving these variables. We work being flexible, reliable and available.